Saturday July 5th 2025

Saturday July 5th 2025

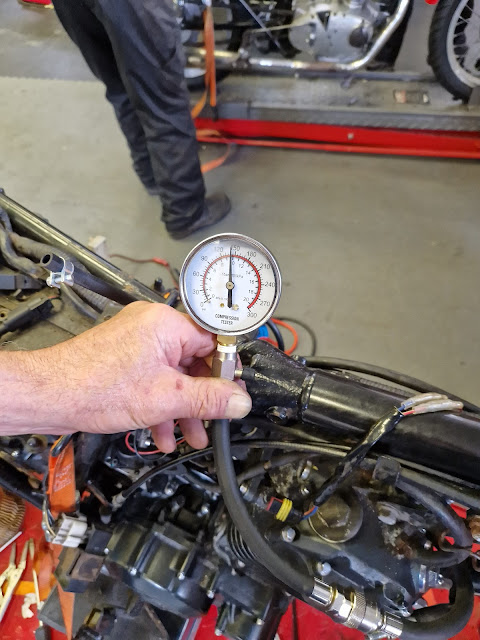

Mash 400 dirt star…

We had received a donation of tools, amongst the tools was a starter pack. It was quite old and looked well used and after Don reconnected the crocodile clip, we tried it on the mash. At first it didn’t seem to make any difference however, later in the session we tried it again. This time, not only turn the engine quickly but also kept on turning it quickly. This produced lots of flames from the exhaust plus some black smoke, plus the sound as if the engine is going to start. However, it just wouldn’t touch and keep running. With the engine now turning fast enough the compression test Heinz and I fitted the compression tester and spun the engine over. The compression tester showed a peak of 145 psi and he did this twice. This showed us that the engine had excellent compression. I removed the air filter in case a rat (Or similar creature) had taken up residence in the air filter housing. But alas, no and in fact the air filter was reasonably clean. The fuel injector itself wasn’t fully tightened up so it was removed and replaced and tightened once its O-ring seal had been checked. I even got the neon spark plug cap to make sure there was a healthy continuous spark and there was. So we had fuel, compression and spark but the engine would not catch and run. Whatever would we do next?

|

| Mash 400 has around 145 PSI, more than enough to start and run. |

|

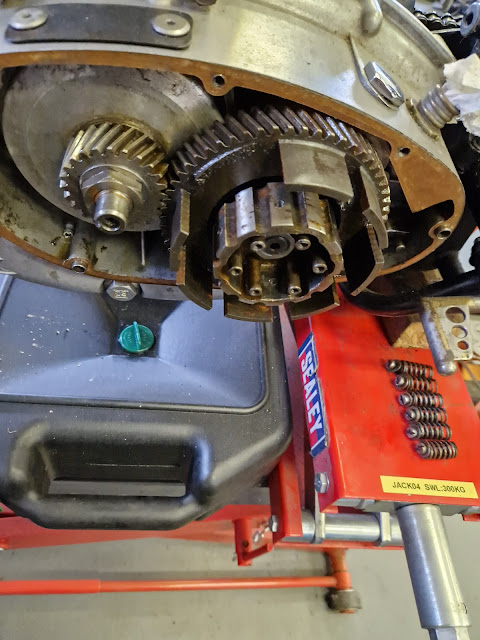

| The Ducati clutch worked OK once freed up but would this cause problems?? |

Suzuki GSF1200 Bandit.

With a little guidance from me Roger and Don set about checking the valve clearances of the Bandit. With minimal difficulty, the rocker cover was removed. Everything inside the top of the engine looked tickety-boo. The camshaft lobes looked perfect. So it was out with the plugs, put the bike in gear and use the back wheel to turn the engine over. The inlet valve clearances should be 0.10 to 0.15mm and the exhaust should be 0.20 to 0.25 mm. The feeler gauges we had were imperial, so we chose feeler gauge blades roughly midway between the two extremes. Using a tappet adjuster tool that I eventually found in the toolbox box we got each gap so that the blade was a fairly tight sliding fit, so that it could be guaranteed to be between the two extremes. Quite a few valves were on the loose side and three or four were too tight. Next time around the rocker cover would hopefully get a respray and be refitted with the new rubber seal that had been supplied wth the bike when it was donated.

Z250 Scorpion (Circa 1980)

Keiran was happy to see that workshop Santa had delivered a new Speedo and rev counter cable to the workshop, but was far too busy to fit them.

Jiailing 125 trials bike project.

Keiran had been too busy during the week to tackle sealing the inside of the tank, but there was no rush. I had finally managed to obtain the correct 22mm handlebar grip to install on the left-hand end of the handlebars.